4737-263-T1

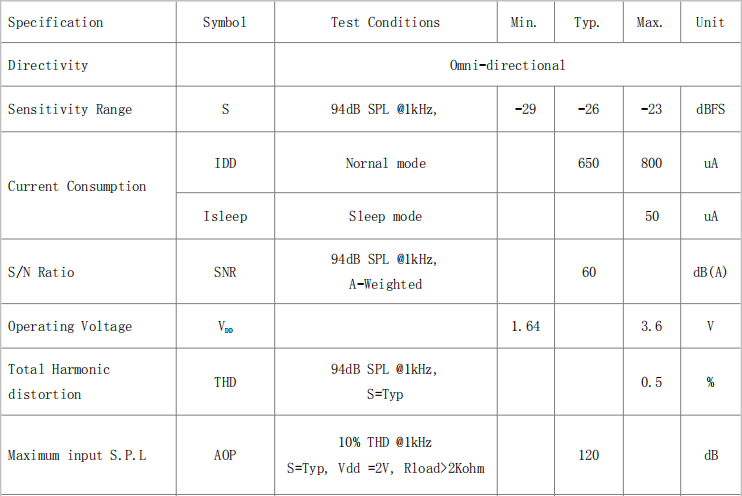

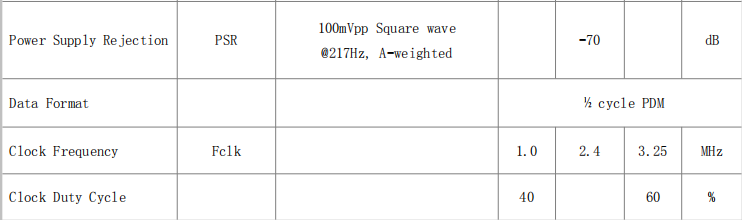

1. Electrical specifications

Test conditions :Vdd=1.8V, Fclk= 2.4mhz, L/R ground, 23±2℃, 55±10%R.H. , unless otherwise specified.

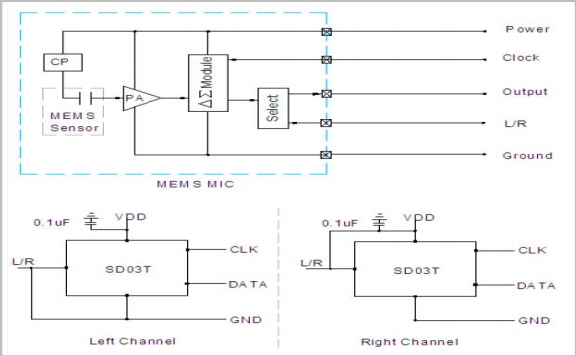

2. Application circuit

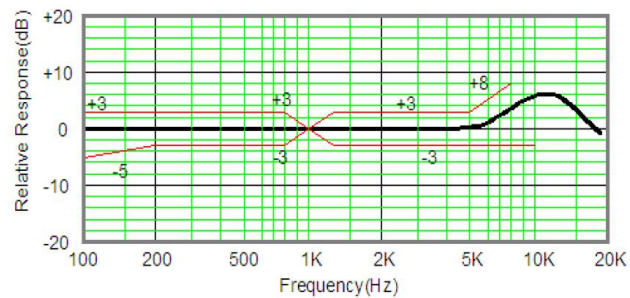

3.frequnency Response

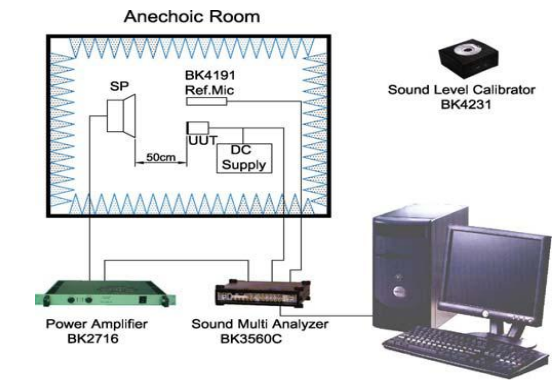

4. Measurement system:

5. Reliability test

All tests shall be carried out in the same batch of tests in the sequence listed. The sensitivity should be within ±3dB of the initial sensitivity after 2 hours of restoration at 20℃

Temperature test: Sensitivity should be within ±3 dB from initial value after 200 hours of exposure at 60°C. After 200 hours of exposure at -25°C, the sensitivity should be within ±3 dB of the initial value.

Humidity test: After exposure for 200 hours at 60±3℃ and relative humidity of 90~95%, the sensitivity should be within the initial value ±3 dB.

Temperature cycling test: Sensitivity should be within the initial value ±3 dB after 15 cycles of exposure at -25°C for 30 minutes, 20°C for 10 minutes, 60°C for 30 minutes, and 20°C for 10 minutes.

Vibration test: In order to ensure that the vibration after use is not affected, 10 Hz ~ 50 Hz test is carried out for 1 minute at the full amplitude of 1.52 mm and for 2 hours at 3 large angles

Drop test: In order to ensure that the test microphone in the package falls off and does not affect its use, the 3 sides of the package are dropped from a height of 1.5 meters on the cement floor for 12 cycles

Electrostatic protection: The test microphone must discharge between each ESD exposure point (contact point :±6KV, air :±8KV)

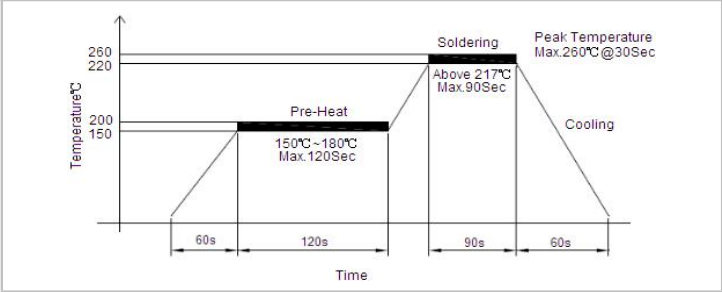

6. Reflux profile (to ensure maximum reflux conditions):

Reflow soldering is recommended, reflow soldering temperature <=260℃(peak temperature lasts 30 seconds)

Important precautions to reduce equipment damage:

1. Do not clean or clean the veneer after the reflux process.

2. Pressure exceeding 0.3mpa shall not be applied to the interface hole.

3. Do not expose to ultrasonic treatment or cleaning.

4. Do not pull the vacuum cleaner through the microphone hole.

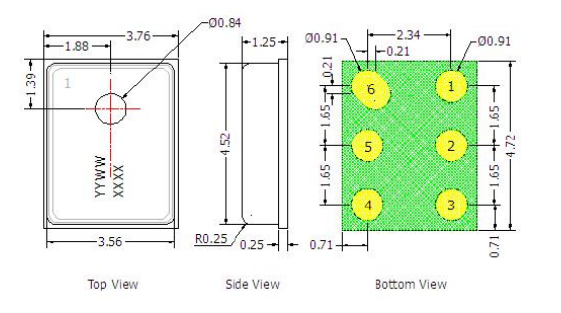

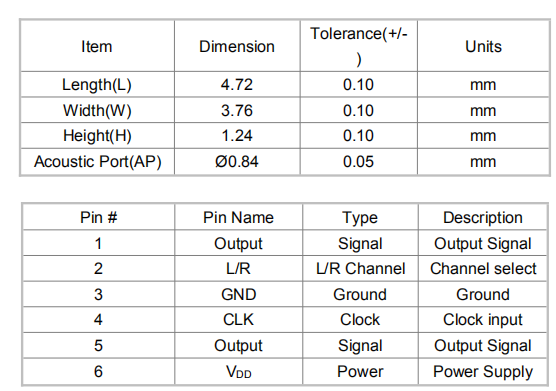

7. Mechanical properties

Plate surface cleaning pressure is limited to 0.3Mpa

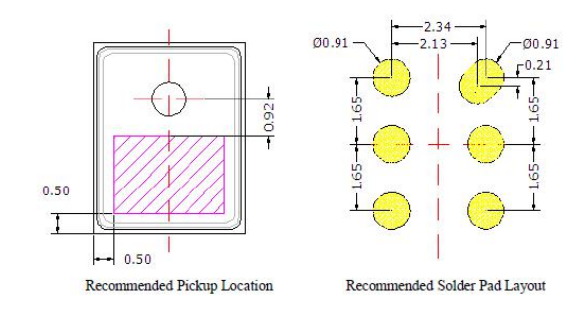

8. Pick up tool pick up position and PCB solder plate layout

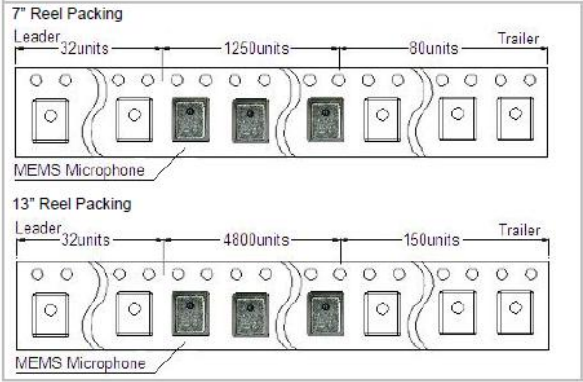

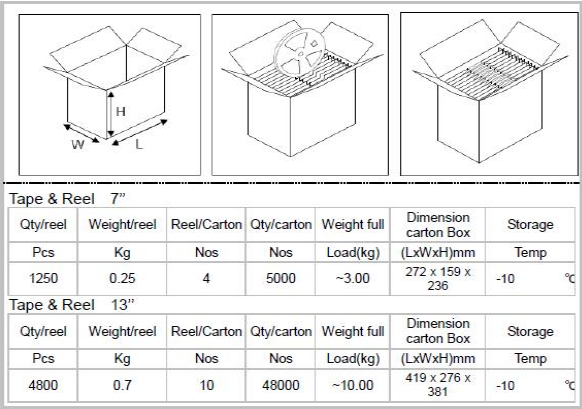

9. Packaging (Unit :mm)